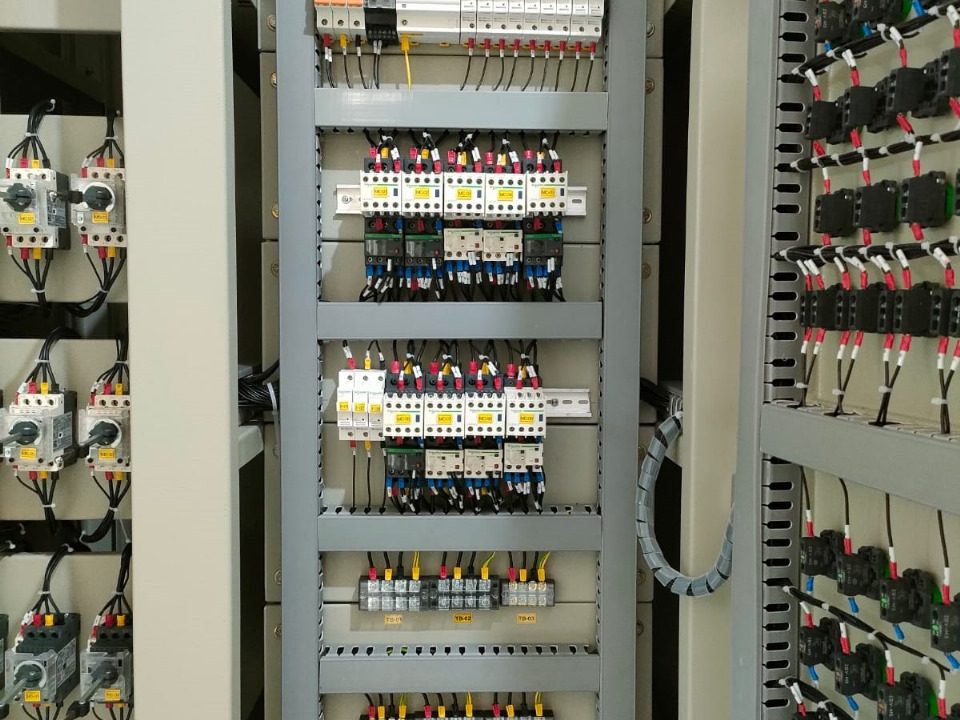

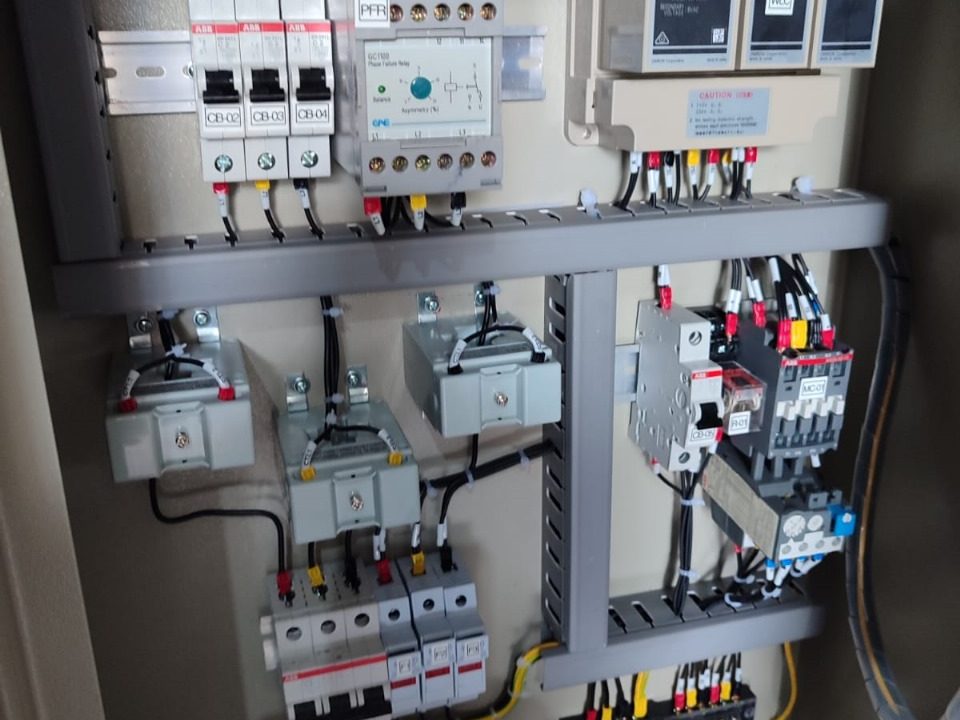

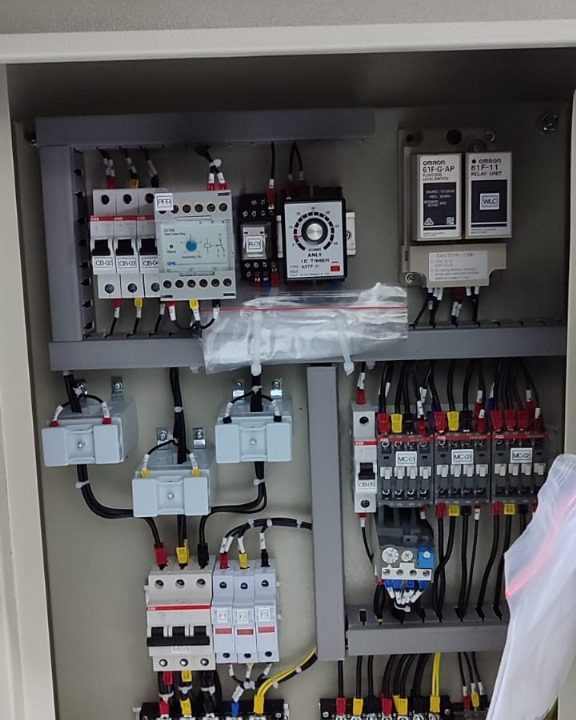

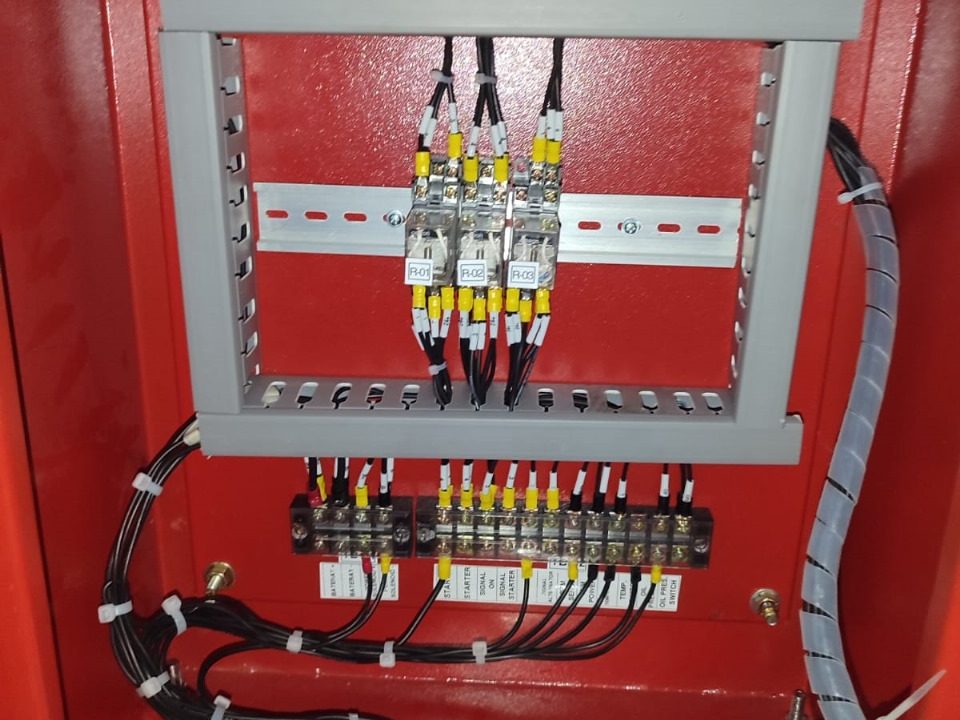

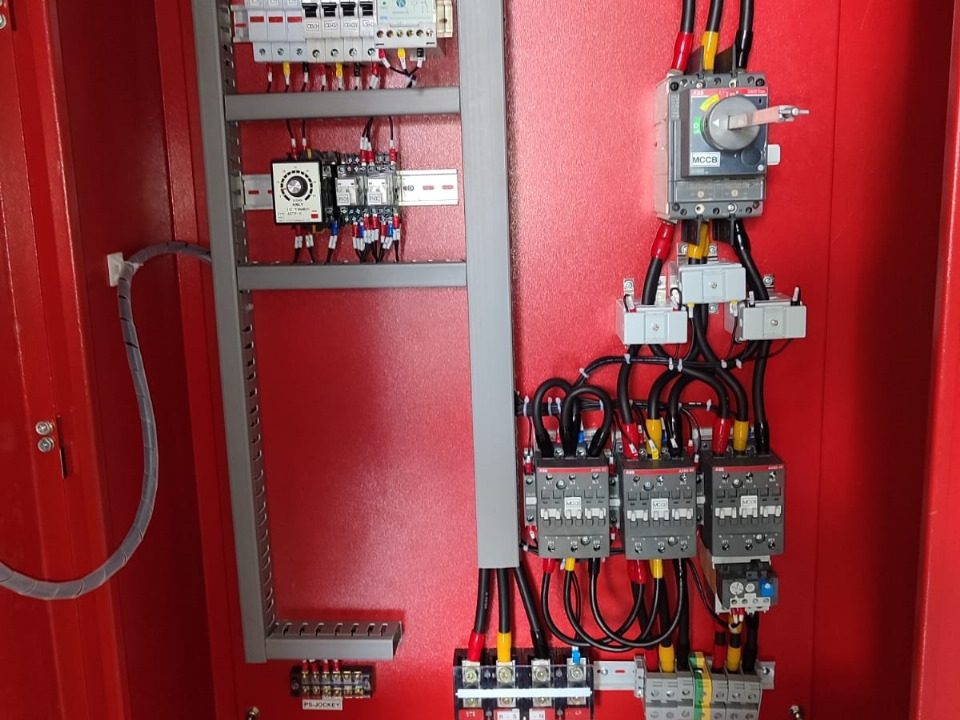

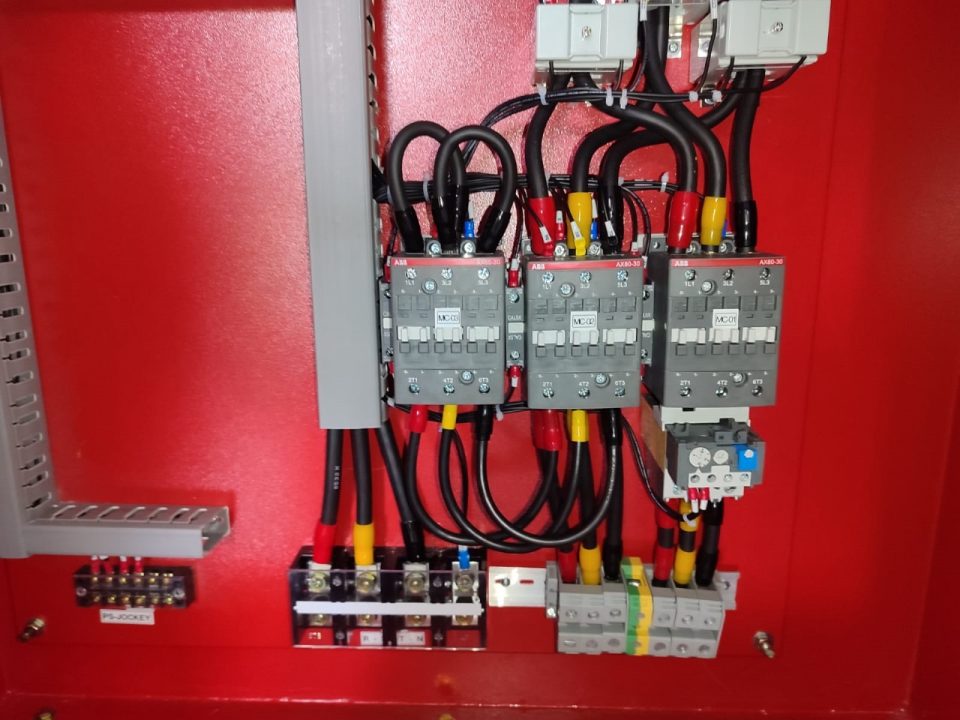

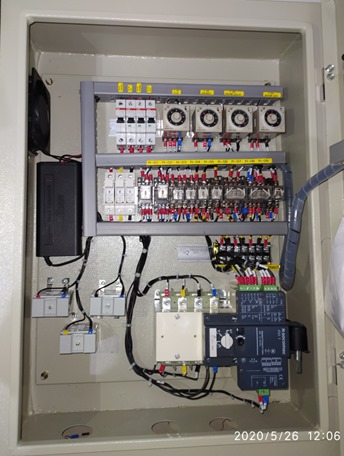

PT. Besa Sekar Guna manufactures panels to a comprehensive panel system including: Inverter Panels, Panel Automation, Capacitor Banks, Soft Starters, Main Distribution Panels (MDP), Sub Distribution Panels (SDP), Star-Delta Panels, Direct On Line Panels (DOL), AMF and ATS Panels.

Application:

- Government Project (PDAM)

- All types of industries

- Commercial estate & real estate

- Hospital, hotel & apartment